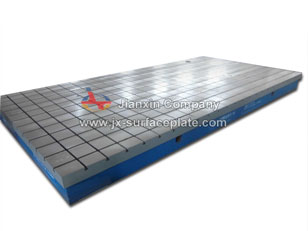

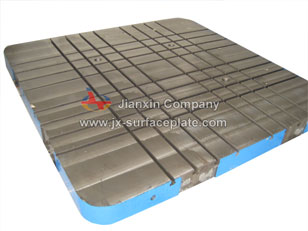

Cast iron surface plate

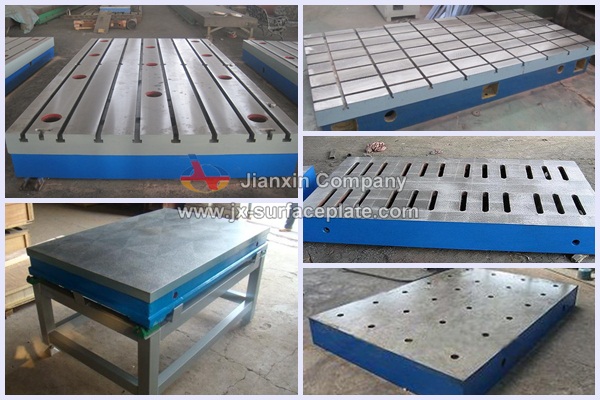

Cast iron surface plate are used in various inspection works and usually as the base plate in precise testing. Check the size precision or geometric tolerances of the components, then marking; they are the fundamental tools in machinery manufacture.

- Category: Cast iron surface plates

- Tel: : +86-317-8177617

- Fax: : +86-317-8175009

- E-mail:: info@jx-surfaceplate.com

Cast iron surface plate

Cast iron surface plate Uses: Cast iron surface plates are used in various inspection works and usually as the base plate in precise testing. Check the size precision or geometric tolerances of the components, then marking; they are the fundamental tools in machinery manufacture.

1. According to the raw material the surface plates can be divided into Cast iron surface plates and granite surface plates.

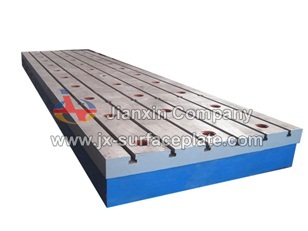

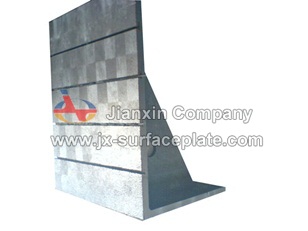

2. According to uses the cast iron surface plate can be divided into inspection surface plate, lineation surface plate, measuring surface plate, assembling surface plate, grinding surface plate, welding surface plate, rivet welding surface plate, basic surface plate, working surface plate and three coordinate surface plate, etc.

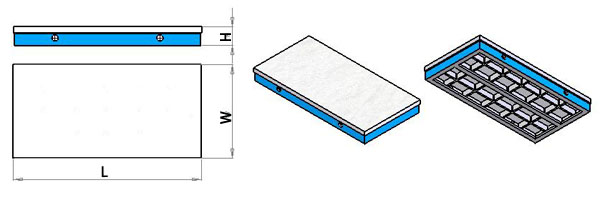

200x200 – 3000x8000mm (special size is acceptable following customers’ requirement)

| specification(Lx W)mm | precision grade | |||

|---|---|---|---|---|

| 0 | 1 | 2 | 3 | |

| flatness tolerance (um) | ||||

| 200×200 | 3.5 | 7 | 14 | 27 |

| 300×200 | 4 | 8 | 15 | 30 |

| 300×300 | 4 | 8 | 15 | 30 |

| 300×400 | 4 | 8 | 16 | 32 |

| 400×400 | 4.5 | 8.5 | 17 | 34 |

| 400×500 | 4.5 | 9 | 18 | 35 |

| 400×600 | 5 | 10 | 19 | 37 |

| 500×500 | 5 | 10 | 19 | 37 |

| 500×600 | 5 | 10 | 19 | 39 |

| 500×800 | 5.5 | 11 | 21 | 43 |

| 600×800 | 5.5 | 11 | 22 | 44 |

| 600×900 | 6 | 11.5 | 23 | 46 |

| 1000×750 | 6 | 12.5 | 25 | 50 |

| 1000×1000 | 7 | 13.5 | 27 | 54 |

| 1000×1200 | 7 | 14 | 29 | 58 |

| 1000×1500 | 16 | 32 | 63 | |

| 1000×2000 | 18.5 | 37 | 74 | |

| 1500×2000 | 20 | 40 | 80 | |

| 1500×2500 | 22.5 | 45 | 90 | |

| 1500×3000 | 25 | 50 | 100 | |

| 2000×2000 | 22 | 44 | 88 | |

| 2000×3000 | 27 | 53 | 106 | |

| 2000×4000 | 32 | 64 | 127 | |

| 2000×5000 | 37 | 75 | 150 | |

| 2000×6000 | 43 | 86 | 172 | |

| 2000×7000 | 49 | 97 | 194 | |

| 2000×8000 | 54.5 | 109 | 218 | |

| 2500×3000 | 28.5 | 57 | 114 | |

| 2500×4000 | 33 | 67 | 133 | |

| 2500×5000 | 39 | 77 | 154 | |

| 2500×6000 | 44 | 88 | 176 | |

| 2500×7000 | 50 | 99 | 198 | |

| 2500×8000 | 55 | 110 | 221 | |

| 3000×3000 | 30.5 | 61 | 122 | |

| 3000×4000 | 35 | 70 | 140 | |

| 3000×5000 | 40 | 80 | 160 | |

| 3000×6000 | 45 | 90.5 | 181 | |

| 3000×7000 | 51 | 101 | 203 | |

| 3000×8000 | 56 | 112.5 | 225 | |

| 4000×4000 | 39 | 78 | 156 | |

| 4000×5000 | 43 | 87 | 174 | |

| 4000×6000 | 48 | 96.5 | 193 | |

| 4000×7000 | 53 | 107 | 213.5 | |

| 4000×8000 | 59 | 117 | 235 | |

Precision grade: 0, 1, 2, 3 and 4 grade following national standard.

packaging is the key point which influences the surface plate deformation or not. Our packaging is wooden box made from manufactured wood products such as plywood, suitable for sea transport and land transport.

1. We should install and debug before using the surface plates.

2. Clean the working surface and start to work as soon as you check there is not any problem. We need to prevent the excessive collision between workpiece and surface plate in case of damages of surface plates’ working surface.

3. The weight of workpiece should be lighter than load rating, if not it will be low down the working quality, damage the structure of surface plates, even wore, it will deform and be unusable.

How many identification items of surface plates include?

There are five identification items together about the surface plates: the appearance and surface quality, roughness of working surface and sides, included angle of sides, contact point of scraping surface plates and the flatness of working surface.

How to protect the Cast iron surface plates from deformation?

In case of any deformation happen during the processing of lifting, must be sure the four wire ropes which steadily hoist the four sides of surface plate in same-length.

When installing, the cast iron adjustable mounts on every supporting pointes should be well adjusted in order to bear averaged force. Our professional specialists are in charge of debugging the surface plates until getting qualified precision grade.

When using, please put down carefully and it is not allowed to move the rough workpieces on surface plates in case of any scratched, dented in places.

After using, please take down the workpieces in case that any deformation happens. When not in use, we need to clean the working surface, coat rust-proof oils, cover with rust-proof paper and package the surface plates with outer packing in order to protect the surface plates in well condition.

Botou Jianxin Cast Iron and Measuring Tools Co., Ltd is established in June 1978, and we restructed in August 2004. We are GB/T19001-2000idt and ISO 9001:2000 certified organization since October 2005.

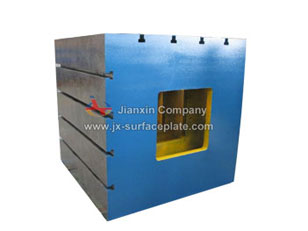

We are a renowned manufacturer, exporter and distributor of cast iron and measuring tools in North of China, for example Cast iron surface plates, Cast iron cubes, cast iron angle plates, T-slots cast iron ground rails, cast iron V-blocks , machinery casting, granite measuring tools, cast iron surface plate accessories, etc.

Our experience and diligence have helped us set up business relationship with customers in different districts and countries.