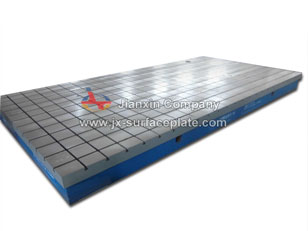

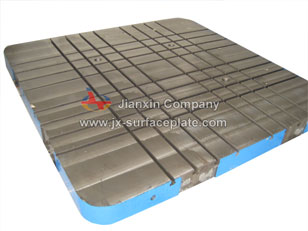

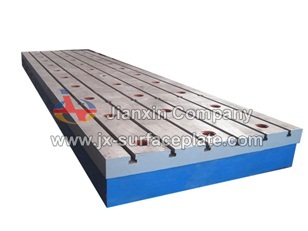

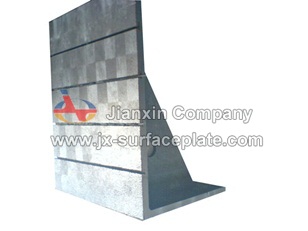

Cast iron floor plates

Cast iron floor plates are also called experimental platforms. They can be used in the dynamic test and debugging of equipments, engines, electric motors and so on. They have well plane stability and tenacity. T-slots are available on their surface for fixing the experimental equipment. Usually the cast iron floor plates are installed at the ground level. If large-scale is needed, join several pieces together is ok.

- Category: Cast iron surface plates

- Tel: : +86-317-8177617

- Fax: : +86-317-8175009

- E-mail:: info@jx-surfaceplate.com

Cast iron floor plates

Usage: Cast iron floor plates are also called experimental platforms. They can be used in the dynamic test and debugging of equipments, engines, electric motors and so on. They have well plane stability and tenacity. T-slots are available on their surface for fixing the experimental equipment. Usually the cast iron floor plates are installed at the ground level. If large-scale is needed, join several pieces together is ok.

Material: HT200-300

Standard: GB/T22095-2008

Specification: 750x1000-3000x8000mm or customize

| specification(Lx W)mm | precision grade | |||

|---|---|---|---|---|

| 0 | 1 | 2 | 3 | |

| flatness tolerance (um) | ||||

| 200×200 | 3.5 | 7 | 14 | 27 |

| 300×200 | 4 | 8 | 15 | 30 |

| 300×300 | 4 | 8 | 15 | 30 |

| 300×400 | 4 | 8 | 16 | 32 |

| 400×400 | 4.5 | 8.5 | 17 | 34 |

| 400×500 | 4.5 | 9 | 18 | 35 |

| 400×600 | 5 | 10 | 19 | 37 |

| 500×500 | 5 | 10 | 19 | 37 |

| 500×600 | 5 | 10 | 19 | 39 |

| 500×800 | 5.5 | 11 | 21 | 43 |

| 600×800 | 5.5 | 11 | 22 | 44 |

| 600×900 | 6 | 11.5 | 23 | 46 |

| 1000×750 | 6 | 12.5 | 25 | 50 |

| 1000×1000 | 7 | 13.5 | 27 | 54 |

| 1000×1200 | 7 | 14 | 29 | 58 |

| 1000×1500 | 16 | 32 | 63 | |

| 1000×2000 | 18.5 | 37 | 74 | |

| 1500×2000 | 20 | 40 | 80 | |

| 1500×2500 | 22.5 | 45 | 90 | |

| 1500×3000 | 25 | 50 | 100 | |

| 2000×2000 | 22 | 44 | 88 | |

| 2000×3000 | 27 | 53 | 106 | |

| 2000×4000 | 32 | 64 | 127 | |

| 2000×5000 | 37 | 75 | 150 | |

| 2000×6000 | 43 | 86 | 172 | |

| 2000×7000 | 49 | 97 | 194 | |

| 2000×8000 | 54.5 | 109 | 218 | |

| 2500×3000 | 28.5 | 57 | 114 | |

| 2500×4000 | 33 | 67 | 133 | |

| 2500×5000 | 39 | 77 | 154 | |

| 2500×6000 | 44 | 88 | 176 | |

| 2500×7000 | 50 | 99 | 198 | |

| 2500×8000 | 55 | 110 | 221 | |

| 3000×3000 | 30.5 | 61 | 122 | |

| 3000×4000 | 35 | 70 | 140 | |

| 3000×5000 | 40 | 80 | 160 | |

| 3000×6000 | 45 | 90.5 | 181 | |

| 3000×7000 | 51 | 101 | 203 | |

| 3000×8000 | 56 | 112.5 | 225 | |

| 4000×4000 | 39 | 78 | 156 | |

| 4000×5000 | 43 | 87 | 174 | |

| 4000×6000 | 48 | 96.5 | 193 | |

| 4000×7000 | 53 | 107 | 213.5 | |

| 4000×8000 | 59 | 117 | 235 | |

Surface: T-slot

Hardness of the working surface: HB160-240

Surface treatment: hand-scraped or finish milling

Foundry process: sand casting or centrifugal casting

Molding type: resin sand molding

Painting: primer and face painting

Surface coating: pickling oil and plastic-lined or covered with anticorrosion paint

Surface flatness: Working, Reference

Precision grade: 2-3

Working temperature: (20±5)°C

Packaging: wooden box