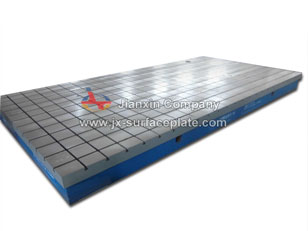

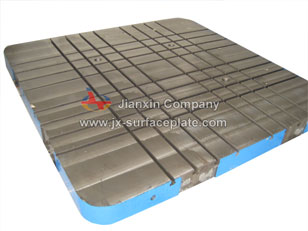

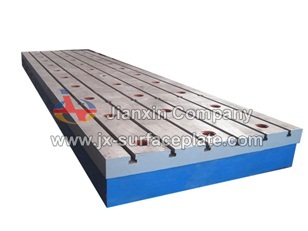

Rivet welding surface plates

Usage: Rivet welding surface plates are used as the basic workbench of rivet welding workpieces and steel metal forming process in the machine processing workshop and sheet metal cold work workshop. Revising or welding on the rivet welding surface plates is also no problem. There are tapped holes or smooth holes on the surface, T-slots are available according to customers' requirement. The long hole is mainly used for clean welding slag and waste. Their advantages are easy to clean, no distortion and in good structure stability.

- Category: Cast iron surface plates

- Tel: : +86-317-8177617

- Fax: : +86-317-8175009

- E-mail:: info@jx-surfaceplate.com

Rivet welding surface plates

Rivet Welding surface plates

Usage: Rivet Welding surface plates are used as the basic workbench of rivet welding workpieces and steel metal forming process in the machine processing workshop and sheet metal cold work workshop. Revising or welding on the rivet Welding surface plates is also no problem. There are tapped holes or smooth holes on the surface, T-slots are available according to customers’ requirement. The long hole is mainly used for clean welding slag and waste. Their advantages are easy to clean, no distortion and in good structure stability.

Material: HT200-300

Standard: GB/T22095-2008

Specification: 750x1000-3000x8000mm or customize

| specification(Lx W)mm | precision grade | |||

|---|---|---|---|---|

| 0 | 1 | 2 | 3 | |

| flatness tolerance (um) | ||||

| 200×200 | 3.5 | 7 | 14 | 27 |

| 300×200 | 4 | 8 | 15 | 30 |

| 300×300 | 4 | 8 | 15 | 30 |

| 300×400 | 4 | 8 | 16 | 32 |

| 400×400 | 4.5 | 8.5 | 17 | 34 |

| 400×500 | 4.5 | 9 | 18 | 35 |

| 400×600 | 5 | 10 | 19 | 37 |

| 500×500 | 5 | 10 | 19 | 37 |

| 500×600 | 5 | 10 | 19 | 39 |

| 500×800 | 5.5 | 11 | 21 | 43 |

| 600×800 | 5.5 | 11 | 22 | 44 |

| 600×900 | 6 | 11.5 | 23 | 46 |

| 1000×750 | 6 | 12.5 | 25 | 50 |

| 1000×1000 | 7 | 13.5 | 27 | 54 |

| 1000×1200 | 7 | 14 | 29 | 58 |

| 1000×1500 | 16 | 32 | 63 | |

| 1000×2000 | 18.5 | 37 | 74 | |

| 1500×2000 | 20 | 40 | 80 | |

| 1500×2500 | 22.5 | 45 | 90 | |

| 1500×3000 | 25 | 50 | 100 | |

| 2000×2000 | 22 | 44 | 88 | |

| 2000×3000 | 27 | 53 | 106 | |

| 2000×4000 | 32 | 64 | 127 | |

| 2000×5000 | 37 | 75 | 150 | |

| 2000×6000 | 43 | 86 | 172 | |

| 2000×7000 | 49 | 97 | 194 | |

| 2000×8000 | 54.5 | 109 | 218 | |

| 2500×3000 | 28.5 | 57 | 114 | |

| 2500×4000 | 33 | 67 | 133 | |

| 2500×5000 | 39 | 77 | 154 | |

| 2500×6000 | 44 | 88 | 176 | |

| 2500×7000 | 50 | 99 | 198 | |

| 2500×8000 | 55 | 110 | 221 | |

| 3000×3000 | 30.5 | 61 | 122 | |

| 3000×4000 | 35 | 70 | 140 | |

| 3000×5000 | 40 | 80 | 160 | |

| 3000×6000 | 45 | 90.5 | 181 | |

| 3000×7000 | 51 | 101 | 203 | |

| 3000×8000 | 56 | 112.5 | 225 | |

| 4000×4000 | 39 | 78 | 156 | |

| 4000×5000 | 43 | 87 | 174 | |

| 4000×6000 | 48 | 96.5 | 193 | |

| 4000×7000 | 53 | 107 | 213.5 | |

| 4000×8000 | 59 | 117 | 235 | |

Surface: V, T, straignt-shaped slots and tapped holes, long holes, grid lines, etc

Hardness of the working surface: HB160-240

Surface treatment: hand-scraped or finish-milling

Foundry process: sand casting or centrifugal casting

Molding type: resin sand molding

Painting: primer and face painting

Surface coating: pickling oil and plastic-lined or covered with anticorrosion paint

Precision grade: 2-3

Working temperature: (20±5)°C

Packaging: wooden box